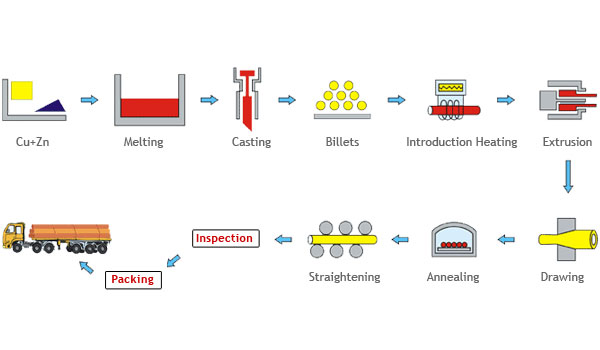

Manufacturing Process

• Raw material:

Collecting copper alloy scrap

• Melting :

Melting Raw material (Copper alloy scrap) @1050°C in Furnace & Addition of zinc and other materials as per Product Material Composition

• Moulding:

Mould molten metal as per product design

• Solidify :

The shape and properties of the solidified metal are then altered through a series of carefully controlled operations to produce the desired brass stock

• Brass stock :

Brass stock is available in a variety of forms including plate, sheet, Strip, foil, rod, bar, wire, and billet depending on the final application

• Hot rolling, cold rolling, extrusion, forging :

Brass stock is available in a variety of forms including plate, sheet, Strip, foil, rod, bar, wire, and billet depending on the final application

• Machining :

Brass stock is available in a variety of forms including plate, sheet, Strip, foil, rod, bar, wire, and billet depending on the final application

• Inspection :

The thickness of the sheet and strip are measured at each step. Finally, samples of the finished product are tested for hardness, strength, dimensions, and other factors to ensure they meet the required specifications.

• Packaging